ENGINEERING SERVICES

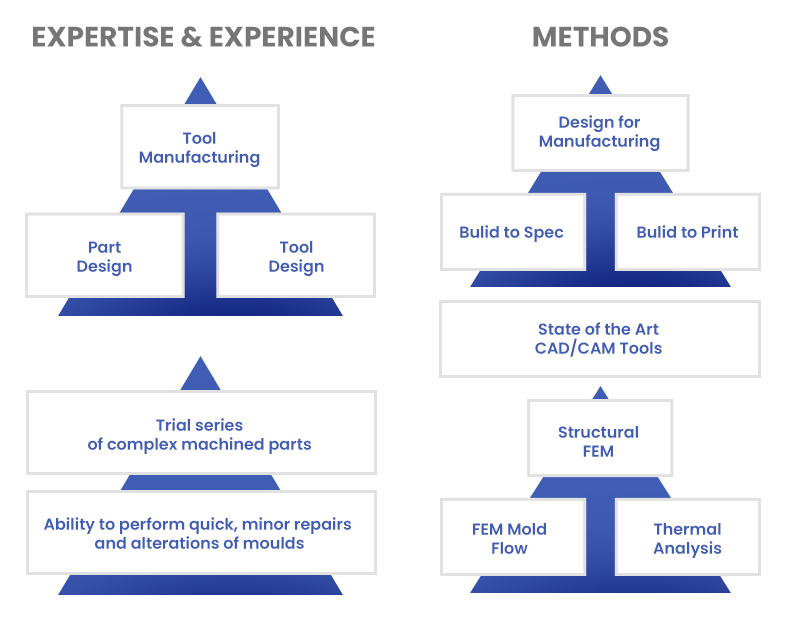

The superior quality of our tools is the sum of all we are doing and putting into. Methods combined with Expertise and Experience are core elements of our engineering Services.

WE OFFER

TECHNICAL CONSULTANCY

at all levels of cooperation optimization of injection mould design based on the planned production, selection of appropriate plastics in terms of technical and economic parameters

COMPREHENSIVE SERVICE

(cooperation ARBO & MIKRO) Idea to Product i.e. product concept, injection mould construction, supervision over mould trials, technological tests, series production (injection)

TOOL MANUFACTURING

& PRODUCTION

These are the major activities of ARBO, where all our expertise and experience of our engineering services effects in superior quality.

We have specialized in three technological groups of action – our Product Lines.

OUR PRODUCT LINES

Your complex designs will be produced on our powerful portfolio of 2-,5-, 6- and 11-axis CNC turning machines. Highly skilled technicians ensure our superior quality standard.

OUR CAPABILITIES

- Diameter range: (1-65 mm) standard, (65-200mm) on request

- Length range: < 600mm

- Accuracy: 0,01 mm

MATERIALS

- Stainless steel

- Free machining steel

- Titanium

- Aluminium & Brass

- Polymers (PEEK)

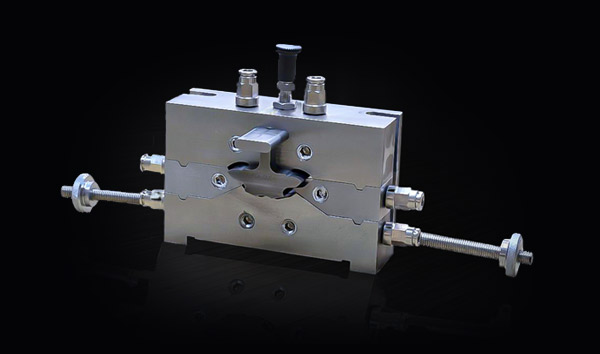

Our expertise in sealing materials goes hand in hand with our product line “Extrusion Tools”

Those tools are produced on 3- and 5-axis CNC machines, operated by our “highly skilled technicians”.

OUR CAPABILITIES

specializing in sealing cutting systems for online & offline

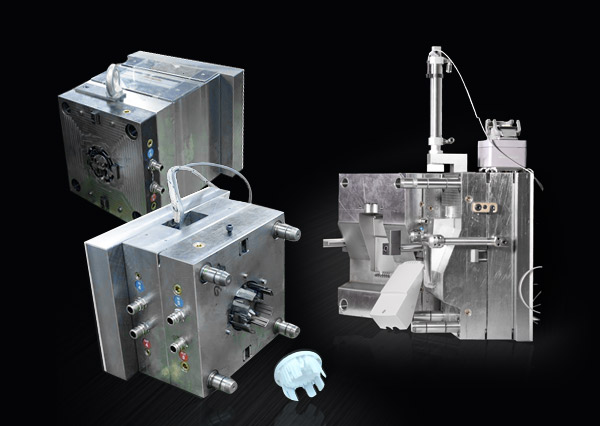

Design and manufacturing of the mould as well as technical consultancy, production trials and series production (by our business cooperation with MIKRO) are our comprehensive Service for you:

From „Idea to Product”

- moulds for plastic injection parts

- production of plastic injection parts (by our business cooperation with MIKRO)

- maximum production size: (500 x 500 x 700) mm3

QUALITY MANAGEMENT

Superior quality is our Core Value.

It is the Start and Finish Point for every activity within our Product Generation Process and of every employee of ARBO.

As such, ARBO established and lives a comprehensive Quality system which generates the base structure of every function.

Because WE

are a professional TEAM!

We never stop improving and gaining in knowledge and experience.

Comprehensive and direct lessons learned closing the circle of the product generation process for every product.

To reinforce our quality approach, we use modern equipment such as CMM of the Swiss company EROWA®.

We are highly skilled, motivated & positive and we are committed to the zero-failure philosophy. This all are core elements of our superior quality.

We think with our customer to enhance their success.