start up of PCV bars manufacturer according to HIT system

WE are ARBO-PRECISION

We are dedicated to technology.

Our target:

Therefore, superior quality is part of every task within our product generation process.

OUR MANAGEMENT

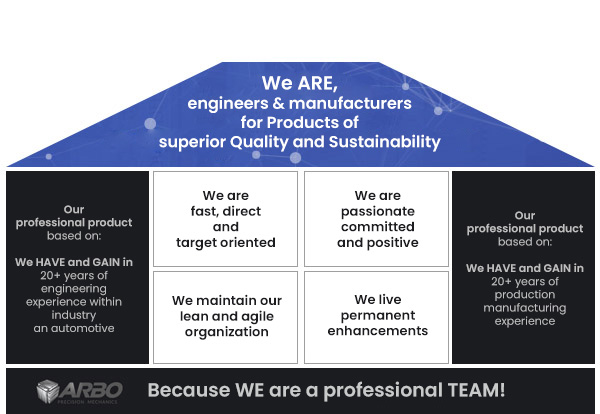

The perfect triangle of:

TECHNOLOGY,

PEOPLE MANAGEMENT &

SUPPORTING PROCESSES plus

QUALITY,

is the Core Structure

of ARBO-PRECISION.

Tomasz Arkabus

Owner & CEO

tomasz.arkabus@arbo-precision.pl

Katarzyna

Arkabus

People Management

&

Logistics

katarzyna.arkabus@arbo-precision.pl

Marzena Arkabus

Quality

&

Customer Care

marzena.arkabus@arbo-precision.pl

ARBO-PRECISION

Professional designer and manufacturer

of tools for extrusion, injection moulds and complex turning/CNC parts

Superior quality is the Start and Finish Point for every activity within our Product Generation Process.

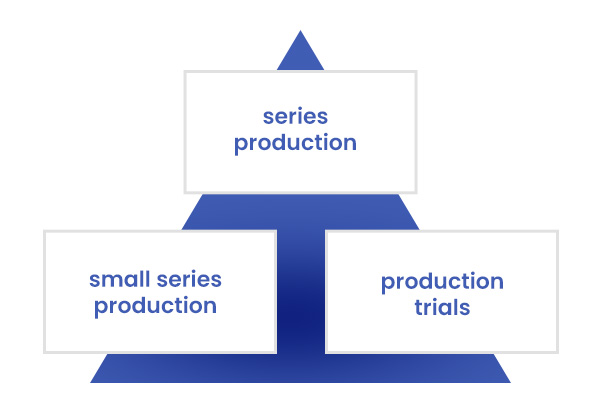

OUR BUSINESS COOPERATION

COMPREHENSIVE SOLUTIONS

ARBO is in a BUSINESS COOPERATION with the company MIKRO.

MIKRO is specialized in manufacturing moulded plastic components.

ARBO and MIKRO are in the same building and have direct access to each other.

for injections moulded parts

COMPREHENSIVE SERVICE

(cooperation ARBO & MIKRO)

Idea to Product

i.e. product concept, injection mould construction, supervision over mould trials, technological tests, series production (injection)

TECHNICAL CONSULTANCY

at all levels of cooperation optimization of injection mould design based on the planned production, selection of appropriate plastics in terms of technical and economic parameters

ARBO & MIKRO

Closing the circle of the solution generation process,

we can apply direct lessons learned and permanent improvement,

to ensure superior quality.

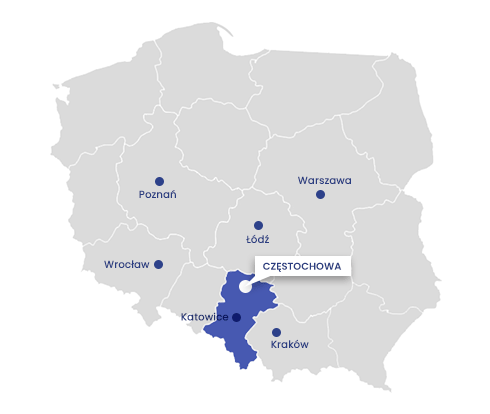

OUR LOCATION

HOME IN POLEN

LOCATED IN EUROPE

We are speaking your language of technology and general communication.

Location in Częstochowa / Poland

- Katowice – 50 km

- Łódź – 126 km

- Kraków – 144 km

- Wrocław – 201 km

- Warszawa – 241 km

OUR HISTORY

Since more than 30 years ARBO is successfully developing and producing solutions for our customers. Ever since, we evolve and grow together with our customers and the markets we are supplying into.

We combine competences and pursuing agile and lean our set target of superior quality.

Within every step of our product generation process, we incorporate the protection of our environment – ARBO thinks green.

Passionate and with comprehensive integrity for

ENGINEERING AND MANUFACTURING,

are looking very positive and responsible, into the future.

15.03.1991

od 2002

service development – foundation of tollshop dedicated to production of injection molds and extrusion tooling

2003

Purchase of Mastercam software to program CNC machines

Obtaining ISO 9001:2000 certificate isued by TUV Suddeutschland Munich

2005

Investment in SolidWorks CAD software package

Start up of extrusion tooling manufacturing to produce car seals

2006

offering complex pieces CNC turning, purchase of CNC machine

2008

another purchase – multi-axis swiss type TORNOS

2010

update of the quality management system to ISO 9001:2008 version

2012

Procurement of multi-axis japanese CNC machine MURATEC

Purchase of Esprit software package for purpose of programing multi-axis CNC machines

2015

purchase of 2 swiss EDM machines by AGIE both equipped with a robot

2017

PVC bars production termination

2018

quality management system adjust to ISO 9001:2015 version

Aviation industry customer contracted

Investment in LIFT 250 Erowa crane in order to improve ergonomy and efficiency of our workforce.

2021

Investment in a new milling machine CMX 50 U

2022

Purchase of 2 LIFT 250 Erowa cranes to improve ergonomics and efficiency of our workforce;

Investment in 2nd EROWA CMM

2023

Investment in a new lathe turning machine Tornos DT26 for the launch of series production of new brass turned parts

CORPORATE RESPONSIBILITY

ENVIRONMENTAL POLICY

Driven by a sense of shared responsibility for the state of the natural environment and with care for its protection, the Owner, and Employees of ARBO make every effort to minimize the harmful impact on the environment resulting from the activities of the organization, while respecting the principles of sustainable development.

OUR ENVIRONMENTAL GOALS

- acting in accordance with applicable legal requirements and other regulations related to environmental protection applicable in the organization’s operations,

- continuous improvement of environmental activities based on the ISO 9001: 2015 standard,

- environmental protection, including pollution prevention,

- rational use and saving of water, energy, and fuels,

- pro-ecological waste management ensuring appropriate segregation, reuse, or disposal in accordance with the requirements of environmental protection law,

- prevention of breakdowns and extraordinary threats to the environment.

IMPLEMENTATION OF THE ENVIRONMENTAL POLICY

takes place through:

- raising employees’ awareness of environmental protection (everyone is responsible for the environment),

- taking actions to ensure the ecological balance in the consumption of raw materials and the amount of waste produced,

- implementation of technical solutions to prevent pollution and environmental threats,

- improvement of production processes,

- constant supervision of machines, devices, and infrastructure.